How do you make black PVD tactile indicators?

The main 4 steps of making black PVD tactile indicators

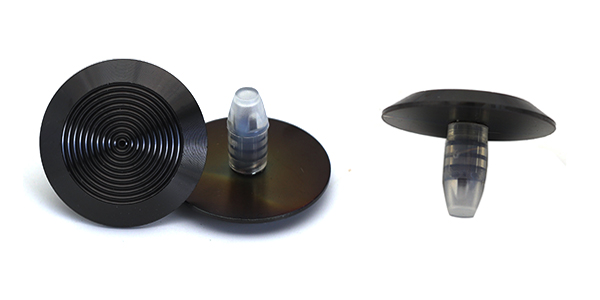

We know that tactile indicators are placed on the road for visually impaired people or blind people to feel the ground through the soles of their feet to determine whether they should stop or continue moving forward. The purpose of these indicators is: To avoid stairs, traffic lights, or obstacles in front of them, black PVD tactile indicators are often laid not only to increase contrast in certain areas to help the visually impaired but also to enhance the beauty of urban Spaces.

So how do you make black PVD tactile indicators?

We use PVD technology. As mentioned in the previous article, this technology it's super durable and resistant to corrosion and is widely used in various fields of life.Here are the main 4 steps to making PVD tactile indicators:

1. Remove the oil from the CNC tactile studs, and clean them. Then soak the nails in water and add a specific coating solution. After soaking for 1 hour, the worker will dry the studs One by one with a clean cotton cloth. During the wiping process, a mask and gloves must be worn to prohibit communication, because even a drop of saliva and a little fingerprint stuck to the nail will have defects.

2. The professional master will tie the nails to the bracket in turn, and each stud must have a specific distance. If it is too close or accidentally overlapped, the studs will become colored.

3. After fixed, it is sent to the coating box by a professional master to control the uniform coating, which is very important, and the master's technology affects the color of the whole batch of Tgsi Tactile Studs.

4. Last, let it cool for half an hour and then put it into the foam board for 2 days until the color is stable and inspected by professional workers.Quality inspection should be done outdoors in a cool place, preferably in the morning from 7:00 to 9:00 and from 3:00 to 4:00 PM when the light isn't too strong. This will make it easier to spot any defects on the surface of the stud. Workers should wear clean new thick thread gloves and rub the surface hard to pick out any blemishes or spots of color.

These four steps are crucial in making black PVD tactile indicators, which is a complex process that requires patience and care to create high-quality products. With 15 years of experience producing tactile indicators and stair nosing, our workers have at least 5 years of experience each. We can guarantee product quality and offer you a factory price.

English

English Chinese

Chinese